Top Butterfly Valves for Sale What to Look for in 2026?

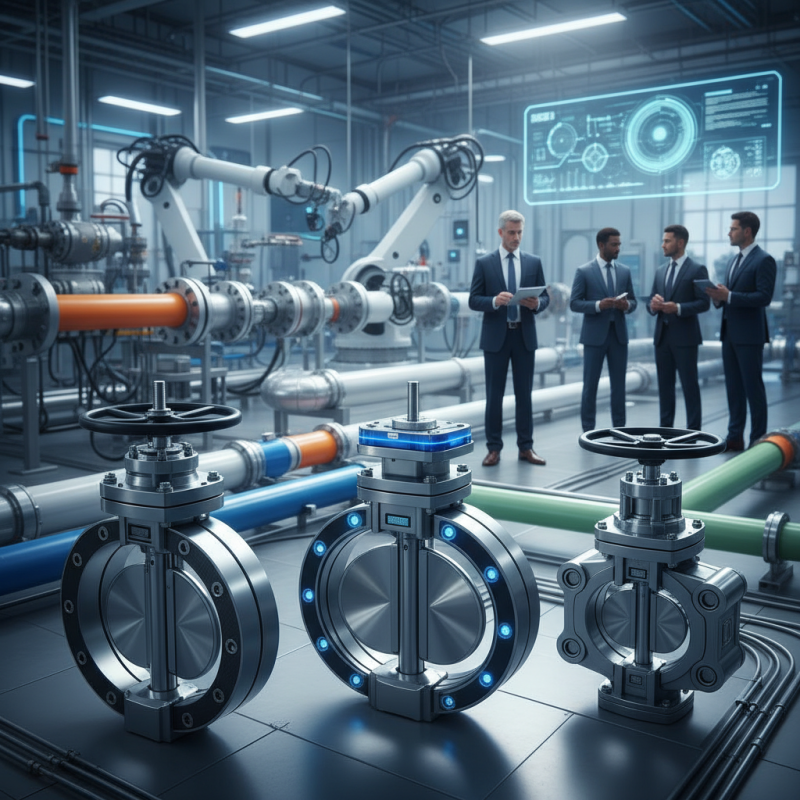

As the demand for efficient fluid control systems rises, the focus on butterfly valves for sale intensifies. Industry expert John Smith notes, "Choosing the right butterfly valve can impact overall system performance." For those considering purchases in 2026, understanding key features will be essential. The market is full of options, which may cause confusion.

Butterfly valves vary widely in design and functionality. Some offer better durability and pressure resistance than others. Many buyers overlook these critical factors when making a purchase. It's important to consider not just the price, but also the long-term benefits of a quality valve.

In 2026, look for brands that emphasize innovation. Valves with advanced materials will likely outperform traditional ones. However, always question what claims manufacturers make. Some products may not deliver as promised. As awareness grows, so will the need for informed decisions regarding butterfly valves for sale.

Top Considerations for Choosing Butterfly Valves in 2026

When selecting butterfly valves in 2026, several key factors must be considered. The material of the valve plays a critical role in performance and durability. According to a recent market report, stainless steel valves dominate the industry due to their corrosion resistance. Yet, plastic options are gaining traction for specific applications where weight and cost efficiency matter.

Another important aspect is the valve size and type. A 2023 industry survey indicated that over 30% of users experienced performance issues due to improper sizing. Failing to match the valve size to your system can lead to leaks or pressure loss. Even though it may seem trivial, the right fit significantly impacts operation efficiency.

Lastly, the actuator type is often overlooked. Electric and pneumatic actuators are prevalent, each with unique advantages. A report from a leading engineering firm shows that 40% of valve malfunctions can be traced back to actuator selection. Understanding your system needs can prevent costly downtimes and frustrations. As the industry evolves, acknowledging these factors can help improve decision-making in 2026.

Key Features to Evaluate in Butterfly Valves for Optimal Performance

When looking for butterfly valves in 2026, specific features matter greatly. Valve size is critical. An appropriate size ensures efficient flow and stability. Inspect the material used in the valve body. Common options include cast iron, stainless steel, and PVC. Each material has its strengths and weaknesses, depending on the application.

Another important aspect is the design of the disc. A well-designed disc enhances sealing capabilities. This can improve overall performance significantly. Additionally, consider the valve's pressure rating. Make sure it meets your system's requirements. An inappropriate rating can lead to failures and costly repairs.

Also, pay attention to the actuator type. Manual, electric, or pneumatic actuators each offer different benefits. Evaluate which one suits your needs best. However, remember that choosing the right actuator isn't always straightforward. You might find your initial choice lacking. Misjudgments in actuator selection can affect efficiency and maintenance. Always take the time to reassess your options.

Top Butterfly Valves for Sale What to Look for in 2026? - Key Features to Evaluate in Butterfly Valves for Optimal Performance

| Feature | Description | Importance in 2026 |

|---|---|---|

| Material | Common materials include stainless steel, ductile iron, and PVC, each offering differing levels of corrosion resistance and durability. | Critical for ensuring compatibility with fluid types and environmental conditions. |

| Size Range | Available in various sizes from 2 inches to 48 inches or higher, depending on system requirements. | Essential for fitting into pipe systems and ensuring adequate flow rates. |

| Pressure Rating | Often rated for specific pressure classes (e.g., PN10, PN16, etc.) indicating their suitability for different applications. | Important for safety and operational efficiency in high-pressure systems. |

| Actuation Type | Manual, pneumatic, and electric options available, providing flexibility in operation. | Influences automation levels and ease of operation. |

| Seal Type | Available with various seal types such as elastomeric, Teflon, or metal seated, affecting performance and longevity. | Crucial for minimizing leakage and ensuring reliable sealing under different conditions. |

| Temperature Range | Designed to handle specific temperature ranges, impacting material selection and valve longevity. | Significant for applications involving extreme temperatures. |

| End Connections | Available in various connections such as flanged, wafer, or lug-style to suit different installation needs. | Important for compatibility with existing piping systems. |

Best Brands and Manufacturers of Butterfly Valves to Consider

When exploring butterfly valves in 2026, consider not just functionality but also brand reliability. Industry reports suggest that quality can vary significantly among manufacturers. Some brands deliver exceptional durability and performance, while others may falter in rigorous applications. Look for brands that emphasize innovation. They often lead in technology and design.

Choosing a butterfly valve requires awareness of crucial factors. Materials matter. Stainless steel and plastic options offer varied benefits. Stainless steel is robust but heavier, while plastic is lighter and corrosion-resistant. Analyze the specifications carefully. Often, valves must handle extreme pressures or temperatures. This determines the valve's successful application.

Market Trends Influencing Butterfly Valve Sales in 2026

As we approach 2026, the butterfly valve market is evolving rapidly. Various trends are reshaping sales and user preferences. Increased demand for automation in industries is driving growth. Companies seek efficient solutions that can minimize manual labor and improve control.

Sustainability is another significant trend. Many industries are focusing on eco-friendly options. This shift influences purchasing decisions. Buyers are more aware of energy efficiency. They prefer valves that reduce waste and emissions.

**Tips:** Consider the material and design. Durability is key for long-term use. Take time to research the specifications. Check compatibility with existing systems. A proper fit ensures better performance.

Technological advancements also play a role. Smart valves with IoT capabilities are gaining traction. These valves offer real-time monitoring. Users can make data-driven decisions. However, the complexities of integration present challenges. It’s essential to evaluate the learning curve for your team. Inexperienced personnel may struggle with advanced features.

**Tips:** Focus on training and support. A knowledgeable team can harness the full potential of new technology. Consistent evaluation of workforce skills is crucial for success. Adaptation will pave the way for effective usage in the future.

Environmental Regulations Affecting Butterfly Valve Selection

In 2026, selecting butterfly valves will require careful consideration due to evolving environmental regulations. The demand for eco-friendly products is rising, impacting valve designs. According to a recent industry report, nearly 60% of companies prioritize compliance with environmental guidelines when choosing materials and technologies.

Emission standards are becoming stricter. For instance, the average allowable leak rate for valves has decreased significantly over the past few years. This change forces manufacturers to innovate in sealing technology. Many valves now incorporate advanced materials that minimize leaks and reduce environmental impact. Using robust materials may appear costly upfront, but the long-term benefits justify the investment.

Additionally, industries are evaluating lifecycle assessments. A report by the Environmental Protection Agency reveals that optimizing valve performance can reduce energy consumption by up to 30%. However, not all manufacturers can meet these assessments, leading to a market filled with varying quality. Buyers should be cautious and conduct thorough research to ensure their choices align with sustainability goals.